An exoskeleton system made up of scaffolding pipe used to support workers building a MAS™ system. Replaces the need for a mobile man lift. Easy to assemble no-bolt design uses sleeves and pins to connect all sections. Fully assembled Leg Sections can be transported from structure to structure using a custom Bucket Bracket on a Skid Steer or Front Loader significantly reducing the “take down” – “reassembly” time. One or more platform systems are quickly moved around the SPiFolding™ (patent pending) structure to safely support workers during the construction process.

SPiFolding™ is approximately 18 inches away from the inflatable form system as well as the Corner Cube Form Systems™. SPiFolding™ facilitates the installation of re-bar, dormers and other exterior facades. SPiFolding™ gives the shotcrete nozzle-man a sturdy and secure platform to work from. When it comes time to finish the final layer of shotcrete the surface finishers can easily work from SPiFolding™ following close behind the shotcrete nozzle-man without interference or safety concerns.

A single SPiFolding™ is interchangeable between the MAS-570™ or MAS-1300™ in the same manner as the Corner Cube Form Systems™. Such interchangeability allows a Contractor to build all MAS™ configurations without the need to purchase additional equipment. (Note: a single MAS-1300™ SPiFolding™ system can create two each MAS-570™ SPiFolding™ systems with the addition of an additional Apex ring)

Manufactured in Kenya and the United States, SPiFolding™ is NOW available for shipment.

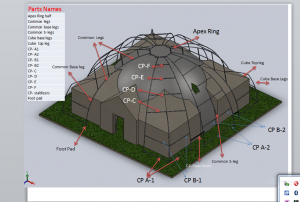

SPiFolding™ V1.0 Parts Diagram is shown BELOW:

SPiFolding in actual use on ACCL Kenya Project (14 Sept 2012) is shown BELOW:

Note: The SPiFolding is the tubular structure that is built around the MAS Forms that appear “inside” the SPiFolding System in the photograph.